Methodology

Vicard Generation 7 Project

The development of new analysis technologies, such as near-infrared spectroscopy, has enabled new wood selection criteria to be defined. In 2009, the Vicard Group embarked on a huge research program to better control the factors that cause variability. These studies have resulted in the development of a completely new brand, named Vicard Generation 7.

This unique brand of barrels based on an analytical selection of woods, is combined with the unique Vicard toasting process. This revolutionary approach has resulted in a range of products with greater precision, uniformity, and reproducibility. Vicard Generation 7 has changed the paradigm of cooperage.

Tannin Potential

Controlling the factors causing variability

University studies over several years has demonstrated the large variability of wood selected based on the forest selection (Snakkers (2000) ; Feuillat (2003) ; Prida (2006)). In addition, these studies proved a wide range of tannin concentrations also exist within the same tree (Masson et Al. (1995)). The selection of staves based on grain size offers more uniform results, however this selection criteria still yields a level of variability between 20 to 40%.

In order to understand these significant differences, we launched an analysis programme, in collaboration with a certified, independent laboratory, on more than 2500 staves. This study enabled us to isolate and define the causes of one important variable: the ellagitannin content in the oak.

Find Out More

Three tannin potential levels

- ORIGINE

- Low Tannin Potential Selection – From 2000 to 4000 µg EGT/g of oak

- SYMÉTRIE

- Medium Tannin Potential Selection – From 4000 to 6000 µg EGT/g of oak

- ÉNERGIE

- High Tannin Potential Selection – From 6000 to 8000 µg EGT/g of oak

Sorting method

Sorting by tannin level occurs after seasoning, machining and scarification of staves (Vicard patent). This analytical process is based on near-infrared spectrometry, enabling three different classes of wood to be distinguished according to their ellagitannin contents (low/medium/high).

Watch the videoMolecular toasting

Sorting by tannin potential segregates highly uniform batches of raw material, however, it is essential to perfectly control the oak toasting process, in order to maintain this uniformity in the final product.

In 2005, Vicard began developing a toasting system that is unique in the cooperage industry. The fully automated system means that the toast profiles can be controlled to + /- 2°C, thus maintaining the uniformity of the raw material.

Thanks to this proprietary process, Vicard Generation 7 adapts to each winemaker’s unique needs by offering innovative toast profiles that respect the balance between the wood’s and the wine’s tannin profile.

Find Out More

Demonstration

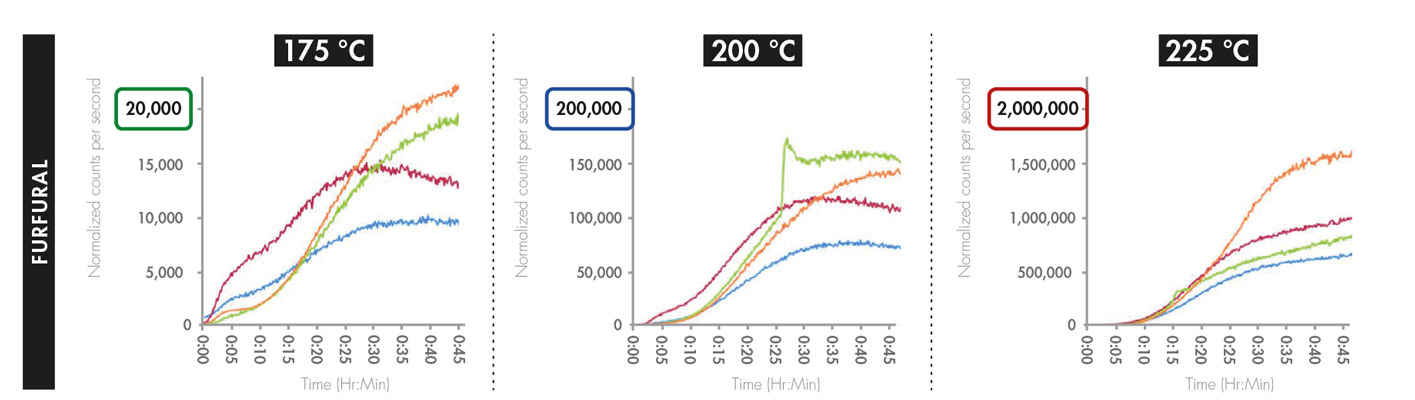

A temperature difference of over 10°C could can cause a large difference in the barrels’ organoleptic characteristics :

Toasting method

Also known as “radiant heat toasting”, it involves applying a controlled, regular and uniform heat to the barrel’s inner surface, using a double-cone furnace, which matches the shape of the barrel. The outer chamber eliminates the variations due to external interferences such as humidity and ambient temperature. This computerized system ensures perfect control of the toasting temperature throughout the entire toast cycle.

Watch the videoImpact of the raw material on the toast

Influence of the tannin potential on the toast

We created an experimental barrel made from staves from the same forest, with the same grain-size and humidity level, but with different tannin potentials (Alternating Low and High TP).

Before the toast, the barrel appeared completely uniform. After the toast, we observed a large variation in coloration (see photo).

This simple experiment demonstrates the huge sensorial impact of tannin potential selection and illustrates the necessity to adapt the toast to the wood’s tannin content.

Find Out More

Before/After toasting

- Before the toast

- The barrel appeared completely uniform

- After the toast

- We observed a large variation in coloration

Sensorial impact

Our methodology enables us to consistently produce barrels with perfectly uniform tannin contents (ellagitannin levels) which respect the vintage’s typicity.